QUALITY

CONTROL

QUALITY CONTROL

QUALITY CONTROL

Here at WTA, we understand the importance of guaranteeing quality at each stage of

the production process to ensure products meet our customers’ standards and

expectations.

We offer a wide range of quality control (QC) services designed specifically for

production in China/ASIA, tailored to different phases of the manufacturing process and

types of product. Below, we offer you a detailed description of each of our quality control

services, together with recommendations about when is the most effective time to apply

them.

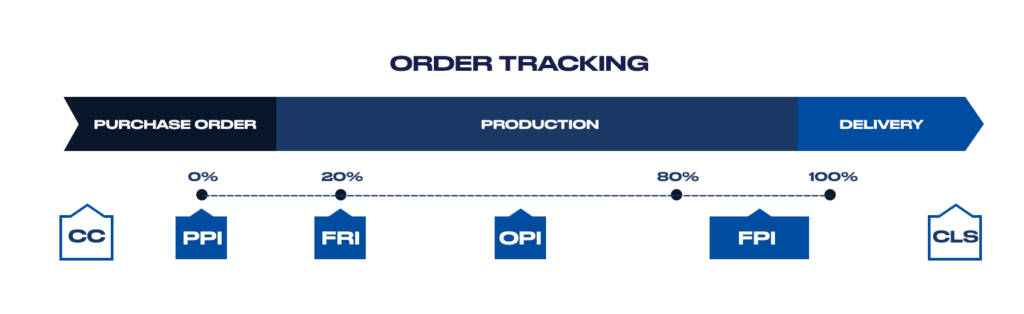

Description: This control is carried out before mass production starts. It includes checking the raw materials, components and analysing the initial manufacturing processes.

When to do it: Recommended for projects with strict material or component requirements, such as electronic products or high quality garments.

Objective: To make sure that everything is ready and that the materials used meet the standards required before production begins.

Description: It is carried out when 20-30% of production has been completed. It includes inspecting products in the assembly line to detect faults early.

When to do it: Ideal for mass productions where continuous quality control is essential, such as general consumer or textile products.

Objective: To detect and correct quality problems before the whole production is complete, minimising risks and costs.

Description: This control is carried out when 80-100% of the production has been completed and is ready to be packaged. It is a random inspection of final products.

When to do it: Recommended for any type of production, particularly in products where the appearance and final functioning are critical, such as with household appliances or toys.

Objective: To check the quality of the finished product before it is shipped, ensuring it meets the agreed specifications.

Description: It is carried out during the process of loading the products into the container.

It includes checking the packaging, labelling and appropriate handling of the products.

When to do it: Particularly useful for fragile or high value products, such as ceramics or electronic equipment.

Objective: To guarantee that products are handled and loaded correctly, minimising the risk of damage during transport.

Description: It is a thorough control that includes inspections at all stages of production, from pre-production to loading supervision.

When to do it: Recommended for critical projects where quality is the maximum priority, such as for government contracts or when launching new products.

Objective: To ensure maximum quality and compliance at all stages of the production process.

REQUEST A CALL WITH A WTA SPECIALIST TO PLAN YOUR STRATEGY

When you entrust your operations in Asia to WTA, you will have a partner with more than twelve years of experience

to take full control of your business operations.